EXPERTISED DESIGNING

Engineering Excellence Through Analysis & Continuous Improvement

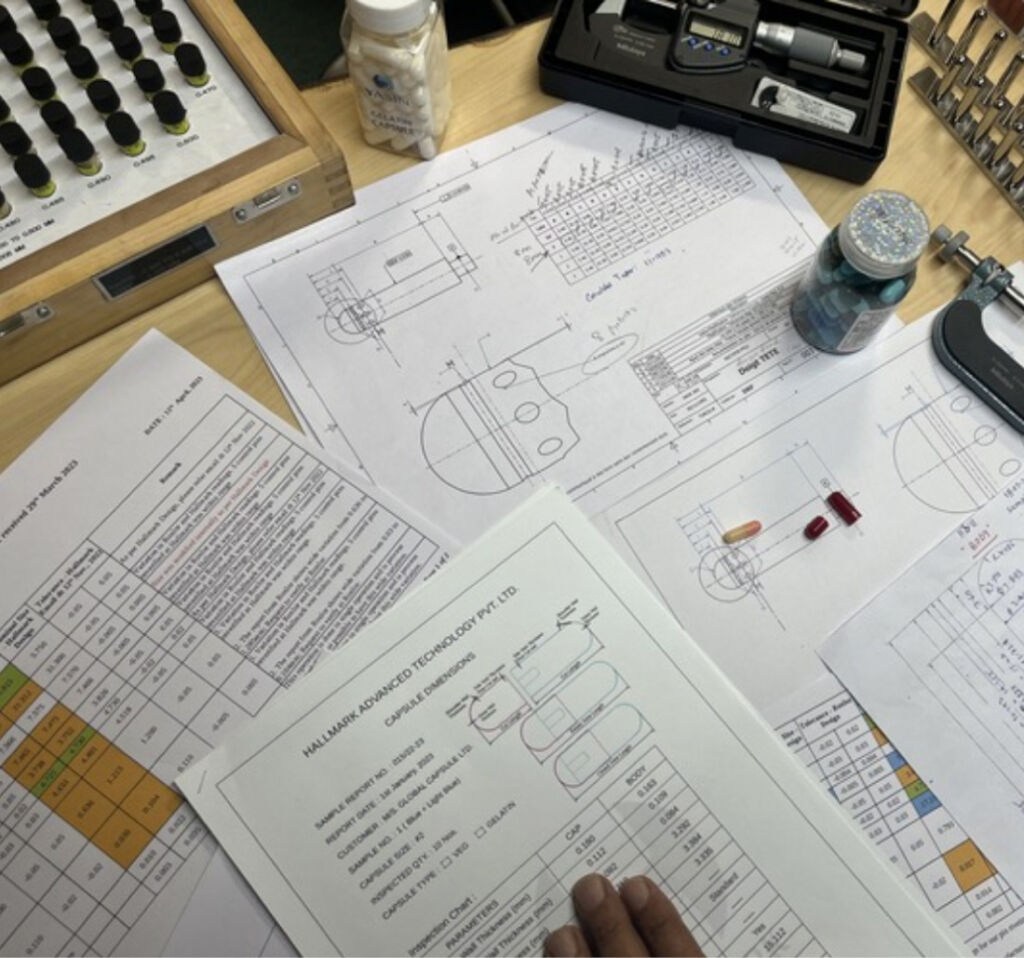

At Hallmark, Pinbar design is driven by meticulous engineering analysis and continuous optimization. Using advanced Finite Element Method (FEM) simulation and analytical techniques, we evaluate each design against our proprietary performance database—built from supplying over 100 Pinbar sets across diverse applications.

This comparative study enables us to refine and optimize every design parameter, resulting in Pinbars that consistently exceed expectations in quality, functionality, durability, and aesthetic precision—ensuring superior capsule performance on filling machines.

No Standard Designs.

Only Optimized Solutions.

Pinbars are not standardized components. At Hallmark, each pinbar is engineered to align with specific capsule formulations, machine parameters, and production requirements. Multiple interdependent factors are evaluated during the design process to optimize capsule efficiency and ensure reliable performance on high-speed filling machines.

a Pinbar Design

Pinbars are not defined by capsule size.

They are application-specific components, engineered around a precise combination of variables—never a one-size solution. Each pinbar design is customized based on:

Gelatin, HPMC, pullulan, and other vegetarian capsule types

Machine type, operating speed, tooling interface, and dynamic behaviour

- Fine powders

- Granules

- Liquids

- Oily or semi-solid formulations

- Volatile or hygroscopic ingredients

These parameters—not capsule size alone—define pinbar geometry and performance, controlling how the capsule forms, fills, locks, and performs throughout its lifecycle.

How We Engineer Performance Into Every Capsule

We translate these inputs into precision-engineered geometries by carefully designing:

How We Engineer Performance Into Every Capsule

We translate these inputs into precision-engineered geometries by carefully designing:

01.Pre-lock shapes and depths

02.Air-vent profiles

03.Locking ring design

04.Dome geometry

05.Taper profiles

06.Cap and body diameter interference

Eliminating Chronic Capsule Issues

are not operational inevitabilities—they are design failures.

Hallmark Pinbars are engineered to eliminate these issues at the source, helping manufacturers avoid long-term losses caused by repeated rejections, inefficiencies, and downtime.

Consider the cumulative cost impact of such issues over years of production.

Seamless Production. Maximum Efficiency.

This allows your technical teams to focus on productivity and scale—rather than firefighting avoidable problems.

Precision-Engineered Pinbars

Hallmark Pinbars are the outcome of a synchronized integration of three critical pillars:

This integrated ecosystem gives Hallmark Pinbars a distinct competitive advantage in terms of dimensional accuracy, consistency, and long-term performance.

Decades of Expertise,

Built Into Every Pinbar

We bring to every project the collective knowledge gained from over 40 years of experience in manufacturing high-precision, mission-critical components for global industries.

Every Pinbar we deliver carries the depth of this expertise—translated into measurable performance on your production floor.