Calibration and Centering

We recognize that investing in state-of-the-art technology and advanced measurement techniques is essential to delivering high-quality products that meet our customers’ exact specifications.

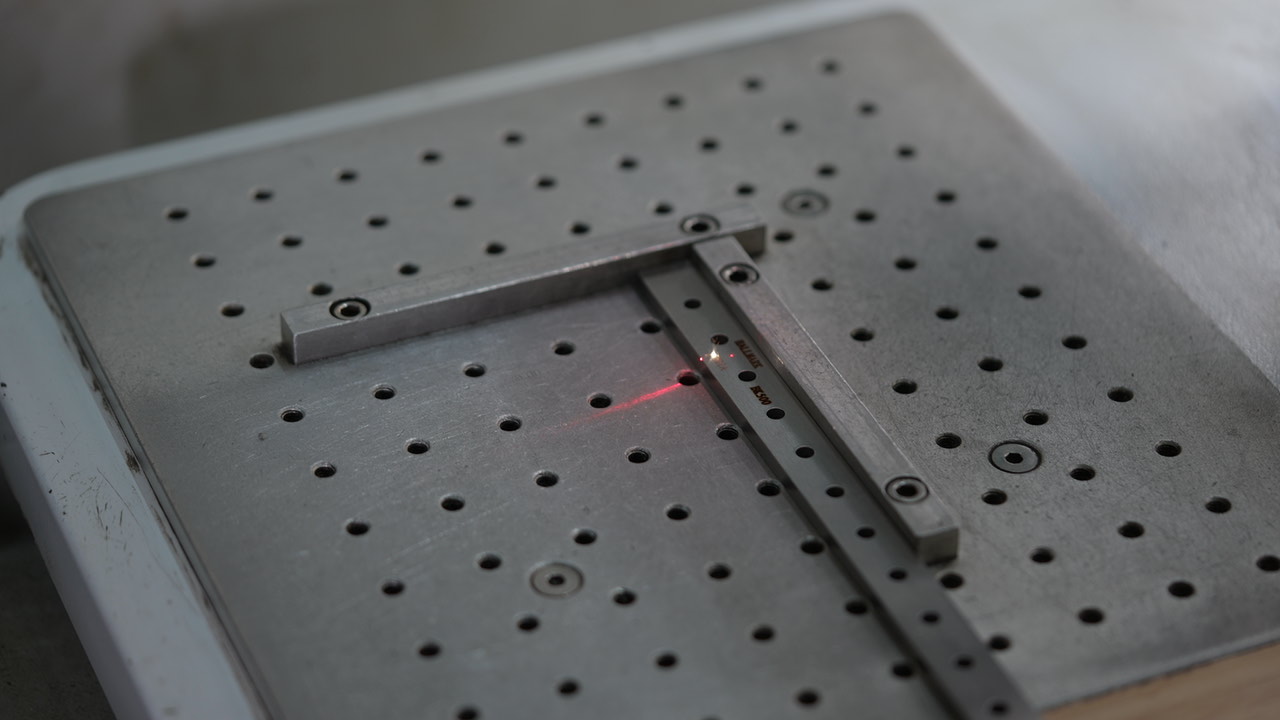

For calibration, we utilize Automated LASER Micrometres, ensuring submicron-level precision with a resolution of 0.00001mm and an accuracy of 0.0005mm.

This fully automated, contactless technique eliminates human intervention, significantly reducing instrument and operator-related errors. The integrated software meticulously scans the entire pin profile, generating submicron-accurate data for all critical parameters.

These advanced laser micrometers, with their high Gauge Repeatability and Reproducibility (GR&R), guarantee exceptional centrality and accuracy of manufactured components.

In a single setting, the system accurately measures and analyzes multiple dimensional parameters, including:

- GPD (Groove Profile Diameter)

- Groove Diameter, Groove Profile, and Groove Length

- Pre-lock Dent Profile and Dent Length

- Air-Vent Profile and Length

Additionally, this sophisticated inspection system is capable of calibrating master gauges, further ensuring consistency and precision across all production processes.

Inspection Methodology

Inspection Methodology

At HALLMARK, we implement a dual-level measurement system to ensure precision and reliability in our quality assurance processes. These complementary methodologies validate each other, reinforcing the accuracy of our inspections.

Our quality assurance framework is built upon:

- Automated Laser Micrometre Readings: Providing submicron precision with a fully automated, contactless measurement system that eliminates human and instrument-related errors.

- Automated Probe-Type Measurements: Offering an additional layer of validation to ensure dimensional accuracy and consistency.

This dual-level inspection approach forms the foundation of our stringent quality control system, guaranteeing that every component meets the highest industry standards.

Advanced Inspection Methodology

At HALLMARK, we employ a dual-tier inspection system to ensure uncompromising precision and reliability in our manufacturing processes.

- Real-Time Contact Probe Measurement

- Each machine is equipped with contact-type probe measurement inspection equipment, enabling continuous monitoring of individual parameters during production.

- Measurement data is wirelessly transmitted to the main Data Server, where it is analyzed for Statistical Quality Control (SQC).

- This analysis generates key insights, including:

- Dimensional histograms

- Standard Deviation (σ) process monitoring

- Machine capability metrics (Cp and Cpk values)

- These insights allow for real-time evaluation of production performance, early detection of anomalies, and immediate corrective action to maintain optimal quality standards.

- Automated Laser Micrometre Verification

- In addition to in-line probe monitoring, samples from each manufactured lot undergo a secondary inspection using Automated LASER Micrometres.

- The measurement data is also transferred and recorded on the main Data Server, ensuring traceability and consistency.

- Real-time production data for each manufactured lot is readily accessible on our systems at any time.

Commitment to Six Sigma Precision

By adhering to the Six Sigma quality standard, we achieve defect levels of less than 3.4 parts per million (ppm). This rigorous quality control approach is critical in maintaining high precision while manufacturing 20,000 pins per day—ensuring superior accuracy and consistency in every component produced.